پمپ ایرلس برقی پیستونی بهتر است یا دیافراگمی ؟

سه شنبه 18 شهریور 1393 -

بازدید: [6502] - گراکو

خلاصه مقاله:

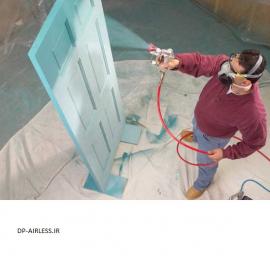

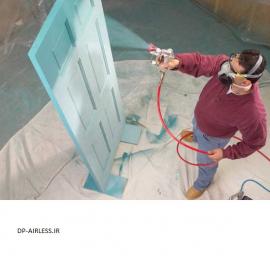

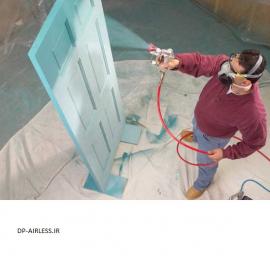

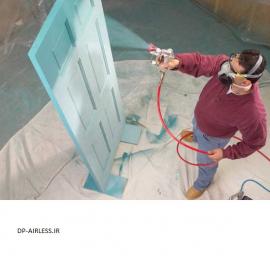

here are many advantages to airless paint spraying. The most prevalent advantage is speed. Airless paint spraying can be over four times faster than painting with a brush, and twice as fast as painting with a roller. Another advantage to airless paint spraying is that you get consistency with your spray. There is even paint coverage with spraying, compared with brushing where you can get thick coatings in one area, and thin coverage in another. The third advantage to airless spraying is adaptability. A person is able to spray multiple coatings, while being mobile at the same time.

متن کامل مقاله:

There are many advantages to airless paint spraying. The most prevalent advantage is speed. Airless paint spraying can be over four times faster than painting with a brush, and twice as fast as painting with a roller. Another advantage to airless paint spraying is that you get consistency with your spray. There is even paint coverage with spraying, compared with brushing where you can get thick coatings in one area, and thin coverage in another. The third advantage to airless spraying is adaptability. A person is able to spray multiple coatings, while being mobile at the same time.

There are two types of pumps, diaphragm and piston. Currently, all Graco airless paint sprayers in production are piston pumps. The advantages 244194 Graco Packing Kitto piston pumps are being able to pump higher-viscosity coatings with ease, there is better atomization, lower maintenance costs, and are easier to repair. The disadvantage to Piston pumps are that they are usually a higher initial price (although they are less expensive to maintain), and there may be fluid fluctuations at lower pressure settings. The advantages to Diaphragm pumps is that there is a tight pressure control and a lower initial price. Although the lower initial price is tempting, there are many disadvantages that can cost you money in the future. There is hydraulic oil leakage, the diaphragm frequently fails, and maintenance costs are usually higher. Other disadvantages are that diaphragm pumps are difficult to prime, they run continuously, and do not perform well with higher viscosity fluidsFluid Section For A Piston Pump

In a piston pump, there are two balls that act like check valves, and control the flow of fluid through the pump. The piston rod connects the internal parts to the motor and gear box. When the piston rod moves up, the fluid section acts like a vacuum, suctioning the paint into the machine. The fluid is then pumped out of the fluid outlet, and into the hose.

A diaphragm pump uses the sprayers motor to create a higher pressure to drive the pump. During the upstroke, the rod moves up, and creates a vacuum within the paint chamber. The vacuum pulls the inlet valve open and the outlet valve is pushed closed by the spring and paint pressure in the hose. Paint is drawn into the paint chamber. On the down stroke, the inlet valve is closed and the outlet valve is forced open as paint is discharged to the sprayer hose.

Inside the pump, there are also a series of o-rings and balls called packings, which create a seal and helps direct the flow of paint. There are two types of packings, throat packings, and piston packings. Throat packings seal the displacement rod to the top of the pump cylinder. Piston packings create a seal inside the cylinder as the rod moves up and down. There is also a reservoir called the wet cup that holds Graco Throat Seal Liquid. TSL prevents paint from drying onto the packings and rod. TSL is clear in color and does no affect the finish of the paint.